My Story about Harvey Wells, Southbridge,

Massachusetts

between the years of 1952 through 1963

submitted by James W. Keaney, Jr. W1AJV

August 3, 2009

After I was discharged from the U.S. Navy I applied for and accepted employment with Harvey Wells, working there from June of 1952 until December of 1963. With a Massachusetts veteran’s bonus of $500 I took an Advanced Electronics correspondence course and, in parallel, was placed by Harvey Wells into an OJT (On-Job-Training) curriculum with my GI Bill Education Program. I was the only OJT employee to be so trained by Harvey Wells.

My training started, according to a government pre-approved plan, an outline for study and hands-on experience, starting at the entry level as a Test Technician on the production line testing the myriad of government contracted military test equipment. My training brought me through almost every element of manufacturing of military equipment. My immediate supervisor was Joe Oleksiak Chief Test Engineer (later to start his own business in Webster, Massachusetts as Olectron), Once I had completed the course on military equipment I was then switched over to their Amateur Radio line of equipment. After completion of this phase I was placed at the end of the line to learn what Quality Control was all about. My immediate supervisor was Mr. Erwin Pederson, Chief of Quality Control.

Occasionally Mr. Cliff Harvey (W1RF) would look in on my progress and was impressed with both the depth of the program and my progress. The next step in the program was for me to acquire some exposure and experience to Engineering starting with small tasks. My job title was changed from Electronic Technician to Assistant Production Engineer and transferred from the Manufacturing Department to the Engineering Department. My immediate supervisor was Mr. Joseph Darche, Production Engineer.

Somewhere along about this time we were hit with the flood of 1955. I was working in the field with another contracted manufacturer in Northern Connecticut when the rains had really increased and I was told that I should head back to Southbridge because of the flooding that was occurring there. I made it back with great driving difficulty and passed over the Southbridge Bridge just before the abutments were washed away and again going over the river before entering Dudley, Mass before it too was washed away. Meantime HW was working on some 20-30 Military trucks converting them for remote airfield operations and control. They were all parked on the river side of the factory and were washed downstream towards the American Optical. The few that were found were so demolished that the government took those vehicles away and the contract was cancelled. .

Mr. Cliff Harvey asked if I could make it back to the plant for cleanup operations and I readily agreed. The mileage from my home was normally 12 miles but because of all the bridges being washed out I had to travel over 45 miles to get back to the plant. I worked on recovering the totally flooded basement stock room materials. I worked in waist high water passing on finished equipment to be placed in the parking lot. Then my attention went to catching all the “floating” vacuum tubes. As the water receded we then had the task of removing all the materials that were totally water damaged and would be scrapped. Part of my reward for flood cleanup was that I could pick out an R-9 Receiver and T-90 Transmitter with power supply and a Z-match to take home. Needless to say, I had to completely disassemble, wash, clean and “cook” much of the parts and ultimately got everything up and running.

Using “flooded” and “refurbished” equipment

Included in my training program was an interim assignment to Mr. Al

Da’Amato (W1???), Senior Project Engineer who introduced me to hands-on

Engineering Drafting experience, working with complete sets of detailed

electronics and mechanical drawings. By the way, for the hams (Amateur

Radio Operators) who read this, Al Da’Amato was the primary Design

Engineer

who developed the R-9 Receiver, the T-90 Transmitter and the Z-Match.

.

By this time Harvey Wells was also working on a Government contract

from Fort Monmouth, New Jersey on assemblies of RF (Radio Frequency)

transmitters

for the AN/TPX-22 Interrogator IFF Radar Transponder used at U. S. NIKE

sites. The HW contract was extended to include the Radar Slot Antenna

AT-352/UPA-22.

With manufacturing electronic and mechanical training and engineering

experience

under my belt, Mr. Harvey recommended me for the start-up of the

Antenna

Project. Now my training will include interfacing with government

civilian employees and, with our Sale Manager, Harry W. Persson

(W1EJD),

received exposure and experience with negotiating strategies.

As the program evolved, I was given full responsibility for the manufacturing, test and final inspection of the antenna and I was promoted to Project Engineer. The contract also involved presenting the completed antennas to a government representative “Source Inspector” for final test and buy-off; with signed paperwork to allow delivery of finished product to Fort Monmouth, New Jersey.

Here, at this point, we have a little more unknown history

connection

involving Southbridge Airport and

Harvey

Wells. One day John Wells (W1ZD)

invited

me to fly with him in his Beach Bonanza to check out a static like

interference

on his radio and, if possible, try to remedy the problem (a loose

ground

strap). Part of testing the AT-352 UPA-22 Slot Antenna was the actual

transmission

of RF energy from the antenna to a distant receiver. The plant parking

lot did not work out at all so this indicated a requirement for a clear

unobstructed field site away from the factory. From my flight with John

Wells I recalled that Stan Krupinsky, Manager of Southbridge Airport,

had

a long grassy strip used for emergency landings. With some

understanding

of electronics and how antennas work, he allowed Harvey Wells to use

his

emergency strip on the basis that it was at our peril if an aircraft

got

into trouble and had to land (we knew that it had been many years since

an aircraft had actually used the strip). Everything had to be removed

each and every day. We finally submitted our plan to the FCC, FAA and

all

military agencies - i.e. Navy, Army, Marines, Signal Corps, etc. After

many delays we were finally cleared for transmission trials. Luckily,

our

prototype antenna was approved during this initial step in the trial

process.

However, these antennas have a range of 137 miles and we were at the

altitude

of the airport with an extended clear view which meant our signals were

being picked by “Neighboring Nike Sites” on their Radar and we were

instructed

to cease and desist all further transmissions. Now we had to find a

test

site at a lower altitude and without a long clear unobstructed view; we

located the perfect site and it happened to be a large cow field, in a

hollow, on Joe Oleksiak’s father’s farm in Connecticut. We mapped very

low power reflected signals on the recorder and we were ready to go.

Initial

trial of high power radiated RF energy, when monitored, was not seen on

the Nike Site’s Radar. So once again we were authorized to “fire up”

the

antennas again. This worked extremely well and the program successfully

continued to the conclusion of the contract without any more problems.

Bay Sate Electronics Corp. entered the picture in June of 1960 and I

was hired as a Production Liaison Engineer and worked there until 1964.

My immediate supervisor was Mr. Frank Kilduff, Plant Manager. They had

a contract from the U.S. Signal Corps for the manufacture of hand held

Walkie Talkies supporting the Viet Nam War. Bay Sate also had a

contract

from Grumman Aircraft at Beth Page, Long Island, New York to produce a

variety of electronic subassemblies for the Navy’s A-6 Intruder. The

most

significant and highly critical assembly were the wiring harnesses that

fit into the wings connecting various electronic systems into the

fuselage.

I had the pleasure of several invitations from Grumman Aircraft Co. to

fly with Stan Krupinski from Southbridge Airport into the Grumman Air

strip

at Beth Page, long Island. On tours of the plant we could quickly

observe

the importance and criticality of our work. We witnessed our assemblies

being integrated into this fine and Viet Nam War proven Airframe. We

were

also introduced to some of the test pilots who congratulated us on the

quality of our work. These A-6’s are still flying today

(07-02-09)

although they are now being phased out of service.

...

...

<<<<<<<O>>>>>> Navy Aircraft Carrier Based A-6 Intruder <<<<<<<<O>>>>>>>>

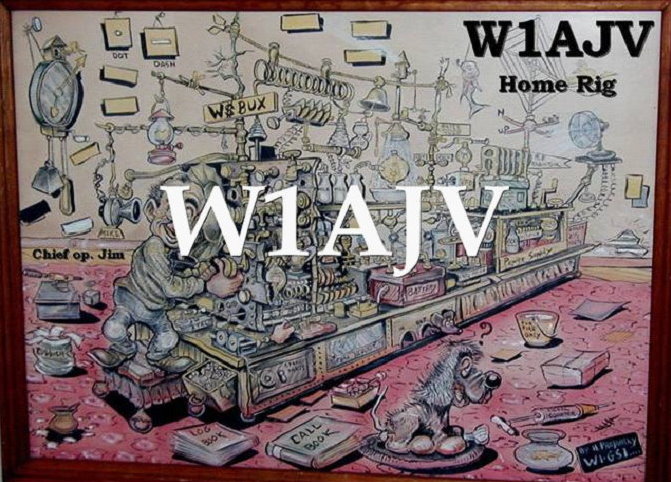

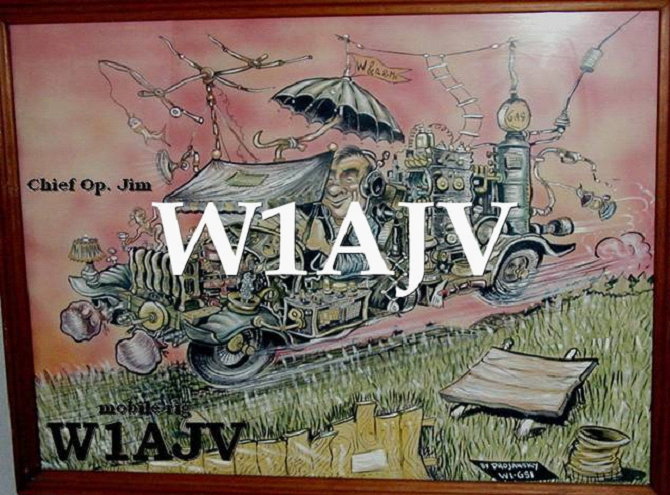

On one of the final days of Mr. Cliff Harvey cleaning out his

office,

he presented me with 2 pastel and charcoal paintings from the

conference

room wall; paintings that he knew I had long admired. .These paintings

reflected his interest in “Ham Radio” as well as the Amateur Radio

portion

of the Harvey Wells business.

These have been purposefully and

temporarily overwritten twice to protect my originals.

Each new dawn is a new beginning ..... Jim

Go

Navy

Al

Watson Recollecions of Harvey Wells and local Ham radio operators

A look back at Harvey-Wells

Electronics

(As it appeared in the Jan 28, 2002 Southbridge News)-

By Dick Whitney